ફ્લોટિંગ બોલ વાલ્વ શું છે?

A ફ્લોટિંગ બોલ વાલ્વના પ્રકારોમાંનો એક છેબોલ વાલ્વ, અને અનુરૂપ એક છેટ્રુનિયન માઉન્ટેડ બોલ વાલ્વ. આમાં એક બિનસપોર્ટેડ બોલ છે જે ફક્ત બે સીલિંગ સીટો વચ્ચે રાખવામાં આવે છે. સ્ટેમ બોલ સાથે લવચીક રીતે જોડાય છે, જેનાથી તે "તરે છે". મધ્યમ દબાણ હેઠળ, બોલ ડાઉનસ્ટ્રીમ સીટ તરફ વિસ્થાપિત થાય છે, જેનાથી આઉટલેટ બાજુ પર એક ચુસ્ત સીલ બને છે.

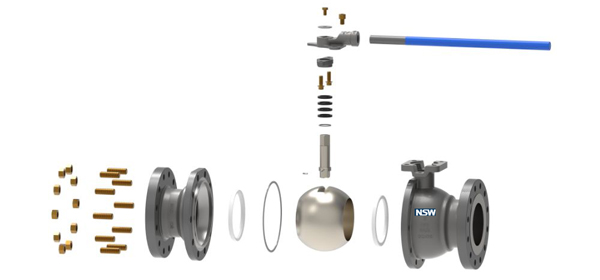

મુખ્ય ઘટકો

• બોલ વાલ્વ બોડી/બોનેટ: વાલ્વના મુખ્ય દબાણ-ધારક ભાગો

• બોલ વાલ્વ બોલ: બોર સાથે મુક્ત ગતિશીલ ગોળા

• વાલ્વ સ્ટેમ: બોલમાં ટોર્ક ટ્રાન્સમિટ કરે છે

• બેઠકો: ડ્યુઅલ સીલિંગ સપાટીઓ

• સીલ: પીટીએફઇ અથવા રિઇનફોર્સ્ડ કમ્પોઝિટ

ટેકનિકલ વિશિષ્ટતાઓ

| પરિમાણ | શ્રેણી |

|---|---|

| કદ (DN) | ૧૫ – ૮૦૦ |

| દબાણ (PN) | ૧.૬ એમપીએ - ૩૨.૦ એમપીએ |

| જોડાણો | થ્રેડેડ (ઇન્ટ/એક્સ્ટ), ફ્લેંજ્ડ, વેલ્ડેડ, વેફર, ક્લેમ્પ |

| તાપમાન | -૧૯૬°C થી ૫૫૦°C |

| સક્રિયકરણ | મેન્યુઅલ/ન્યુમેટિક/ઇલેક્ટ્રિક |

| સામગ્રી | કાસ્ટ/કાર્બન/ફોર્જ્ડ સ્ટીલ, સ્ટેનલેસ |

| ધોરણો | જીબી, ડીઆઈએન, એપીઆઈ, એએનએસઆઈ |

ફ્લોટિંગ બોલ વાલ્વની એન્જિનિયર્ડ માળખાકીય સુવિધાઓ

1. ડ્યુઅલ-સીલિંગ સીટ ડિઝાઇન

માલિકીનું લો-ફ્રિક્શન સીટ મશીનિંગ ઓપરેટિંગ ટોર્ક ઘટાડે છે જ્યારે દ્વિ-દિશાત્મક સીલિંગ દ્વારા શૂન્ય-લિકેજ કામગીરી સુનિશ્ચિત કરે છે.

2. સંરેખણ-પુરાવો સ્ટેમ

ફ્લેટ-કટ સ્ટેમ હેન્ડલ ખોટી ગોઠવણીને અટકાવે છે. સમાંતર હેન્ડલ = ખુલ્લું; લંબ હેન્ડલ = બંધ.

3. સલામતી લોકીંગ છિદ્રો

સંપૂર્ણ ખુલ્લી/બંધ સ્થિતિમાં ડ્યુઅલ લોક છિદ્રો આકસ્મિક સક્રિયકરણને અટકાવે છે - જે જોખમી પાઇપલાઇન્સ માટે મહત્વપૂર્ણ છે.

4. બ્લોઆઉટ-પ્રૂફ સ્ટેમ

એકીકૃત ખભા વધુ પડતા દબાણની ઘટનાઓ દરમિયાન સ્ટેમ ઇજેક્શનને અટકાવે છે, સીલની અખંડિતતા જાળવી રાખે છે.

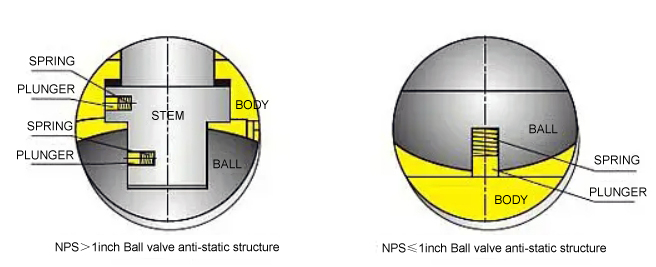

5. એન્ટિ-સ્ટેટિક સિસ્ટમ

ગ્રાઉન્ડિંગ સ્પ્રિંગ્સ ઘર્ષણથી ઉત્પન્ન થતી સ્થિર વીજળી છોડે છે - જે LNG અથવા પ્રોપેન જેવા જ્વલનશીલ માધ્યમો માટે જરૂરી છે.

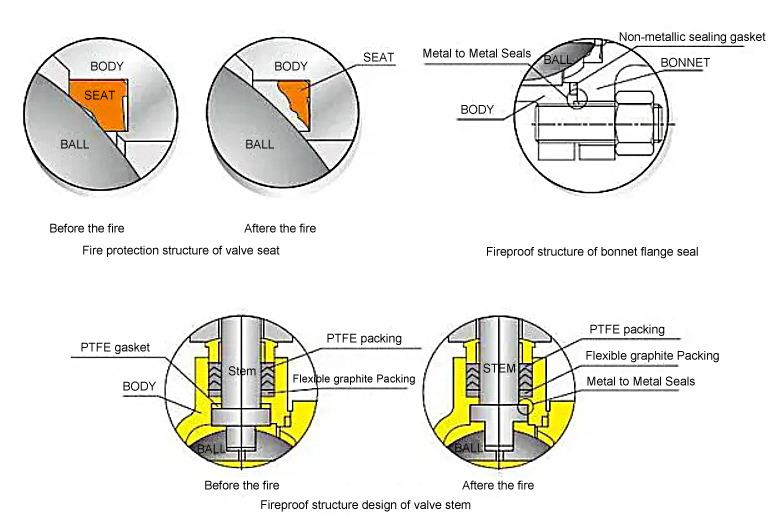

૬. અગ્નિ-સુરક્ષિત બાંધકામ

આગ દરમિયાન ધાતુ-થી-ધાતુ બેકઅપ સીલ કામ કરે છે:

• બળી ગયેલી સીટોને બદલે બોલ/શરીરનો સંપર્ક

• ગ્રેફાઇટ ફાયર સીલ લીકેજને રોકવા માટે વિસ્તરે છે

•API 607/6FA સુસંગત

7. ઝીરો-લિકેજ બોડી જોઈન્ટ

ઇન્ટરલોકિંગ ફ્લેંજ ડિઝાઇન ગાસ્કેટ પરની નિર્ભરતાને દૂર કરે છે, ભારે પરિસ્થિતિઓમાં બાહ્ય લિકેજને અટકાવે છે.

ઔદ્યોગિક એપ્લિકેશનો

• સામાન્ય સેવા: પાણી, દ્રાવકો, એસિડ

• જટિલ માધ્યમો: ઓક્સિજન, H₂O₂, મિથેન

• કઠોર વાતાવરણ:

પેટ્રોકેમિકલ પ્લાન્ટ્સ

કુદરતી ગેસ પાઇપલાઇન્સ (H₂S પ્રતિરોધક)

ક્રાયોજેનિક સિસ્ટમ્સ

ઉચ્ચ-કાટવાળી સ્લરી પરિવહન

ફ્લોટિંગ બોલ વાલ્વના ફાયદા વિરુદ્ધ મર્યાદાઓ

ગુણ:

✓ કોમ્પેક્ટ જાળવણી-મૈત્રીપૂર્ણ ડિઝાઇન

✓ બબલ-ટાઈટ સીલિંગ

✓ ઓછો પ્રવાહ પ્રતિકાર

✓ 90° ઝડપી કામગીરી

વિપક્ષ:

✘ સીટ ઘર્ષણ ઉચ્ચ-P/T ઉપયોગને મર્યાદિત કરે છે

✘ સ્લરી માટે નહીં (ખાંચ ભરાઈ જવાનું જોખમ)

✘ કુશળ ઇન્સ્ટોલેશનની જરૂર છે

સ્થાપન અને જાળવણી પ્રોટોકોલ

સ્થાપન જરૂરીયાતો

• સમતલ સપાટી પર આડી રીતે માઉન્ટ કરો

• બોલની નજીક ફ્લો ટર્બ્યુલન્સ ટાળો

• અવરોધ વિનાની ઍક્સેસની ખાતરી કરો

જાળવણી ચેકલિસ્ટ

• ત્રિમાસિક: ધોવાણ માટે બોલ/સ્ક્રેપર રિંગ્સનું નિરીક્ષણ કરો.

• વાર્ષિક:

લુબ્રિકેટ સ્ટેમ બેરિંગ્સ

ટોર્ક મૂલ્યો ચકાસો

ઇમરજન્સી સીલનું પરીક્ષણ કરો

• બંધ થયા પછી: સ્ફટિકીકૃત થાપણોને રોકવા માટે પોલાણ સાફ કરો

તરતું વિ.ટ્રુનિયન માઉન્ટેડ બોલ વાલ્વ: ટેકનિકલ સરખામણી

| પાસું | ફ્લોટિંગ પ્રકાર | ટ્રુનિયન માઉન્ટેડ પ્રકાર |

|---|---|---|

| સીલિંગ સિદ્ધાંત | મીડિયાના દબાણથી બોલ સીટ પર ધકેલાઈ ગયો | સ્પ્રિંગ્સ સીટોને બોલ તરફ દબાણ કરે છે |

| માઉન્ટિંગ | એકલ ટોચનું સ્ટેમ | ડ્યુઅલ ટ્રુનિયન-સપોર્ટેડ |

| દબાણ રેટિંગ | ≤ક્લાસ ૧૫૦૦ (DN૩૦૦ મહત્તમ) | વર્ગ 2500 સુધી (DN1500+) |

| અરજીઓ | નીચા-મધ્યમ દબાણ પ્રણાલીઓ | પાઇપલાઇન મુખ્ય લાઇનો (દા.ત. પશ્ચિમ-પૂર્વ ગેસ પ્રોજેક્ટ) |

પસંદગી માર્ગદર્શન

વર્ગ 600 હેઠળ ખર્ચ-અસરકારક, કોમ્પેક્ટ સોલ્યુશન્સ માટે ફ્લોટિંગ વાલ્વ પસંદ કરો. હેન્ડલિંગ કરતી વખતે ટ્રુનિયન-માઉન્ટેડ વાલ્વ પસંદ કરો:

• દબાણ > વર્ગ 900

• વારંવાર સાયકલ ચલાવવાના ઓપરેશન

• ક્રાયોજેનિક અથવા ઇરોઝિવ મીડિયા

પોસ્ટ સમય: ડિસેમ્બર-૧૦-૨૦૨૪