બોલ વાલ્વ વિ ગેટ વાલ્વ: શ્રેષ્ઠ પસંદગી માટે મુખ્ય તફાવતોને સમજવું

પાઇપિંગ સિસ્ટમમાં કાર્યક્ષમ પ્રવાહી નિયંત્રણ માટે યોગ્ય વાલ્વ પસંદ કરવો મહત્વપૂર્ણ છે. સૌથી પ્રચલિત વિકલ્પોમાં,બોલ વાલ્વઅનેગેટ વાલ્વપ્રવાહી અને ગેસ પ્રવાહને નિયંત્રિત કરવાના તેમના સામાન્ય કાર્ય હોવા છતાં, તેઓ અલગ અલગ હેતુઓ પૂરા પાડે છે. આ વ્યાપક સરખામણી ઇજનેરો, પ્લમ્બર અને સિસ્ટમ ડિઝાઇનર્સને જાણકાર નિર્ણય લેવાની ક્ષમતા સાથે સશક્ત બનાવવા માટે તેમની ડિઝાઇન, ફાયદા, મર્યાદાઓ અને આદર્શ એપ્લિકેશનોની તપાસ કરે છે.

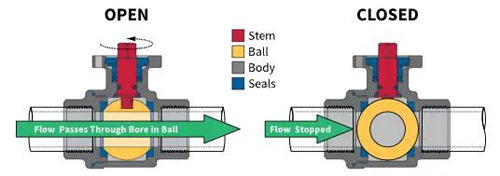

બોલ વાલ્વ: ક્વાર્ટર-ટર્ન શટઓફ સોલ્યુશન્સ

A બોલ વાલ્વએક હોલો, પીવોટિંગ ગોળા દ્વારા કાર્ય કરે છે જેમાં કેન્દ્રિય બોર હોય છે. હેન્ડલને 90 ડિગ્રી ફેરવવાથી બોર ફ્લો પાથ (ખુલ્લા) સાથે સંરેખિત થાય છે અથવા તેને સંપૂર્ણપણે બ્લોક કરે છે (બંધ). ટકાઉપણું અને વિશ્વસનીય સીલિંગ માટે પ્રખ્યાત, તેઓ શ્રેષ્ઠ છે જ્યાં ઝડપી આઇસોલેશન સર્વોપરી છે.

બોલ વાલ્વ લાક્ષણિકતાઓ:

ડિઝાઇન:સરળ બાંધકામ અને ઓછામાં ઓછા ભાગોનું હલનચલન વિશ્વસનીયતા અને જાળવણીની સરળતામાં વધારો કરે છે.

કામગીરી:મેન્યુઅલ લીવર અથવા ઓટોમેટેડ એક્ટ્યુએટર ઝડપી ક્વાર્ટર-ટર્ન એક્શન અને રિમોટ કંટ્રોલને સક્ષમ કરે છે.

પ્રવાહ પ્રદર્શન:ઉચ્ચ-દબાણ પ્રણાલીઓ માટે યોગ્ય, ન્યૂનતમ દબાણ ઘટાડા સાથે ઉત્તમ પ્રવાહ ક્ષમતા પ્રદાન કરે છે.

સીલિંગ:બબલ-ટાઇટ શટઓફ પૂરું પાડે છે, લીકેજના જોખમોને નોંધપાત્ર રીતે ઘટાડે છે

બોલ વાલ્વના ફાયદા:

ઝડપી કામગીરી:તાત્કાલિક ખુલ્લું/બંધ કાર્ય (90° વળાંક) કટોકટી બંધ કરવા માટે આદર્શ.

ઓછો પ્રવાહ પ્રતિકાર: પૂર્ણ પોર્ટ ડિઝાઇન ખુલ્લા હોય ત્યારે લગભગ શૂન્ય દબાણ ઘટાડા પ્રદાન કરે છે.

સામગ્રીની વૈવિધ્યતા: પાણી, તેલ, ગેસ, વરાળ અને કાટ લાગતા માધ્યમો સાથે સુસંગત.

મજબૂત બાંધકામ: મુશ્કેલ વાતાવરણમાં ઉચ્ચ દબાણ અને તાપમાનનો સામનો કરે છે.

બોલ વાલ્વના ગેરફાયદા:

નબળી થ્રોટલિંગ યોગ્યતા: આંશિક ખુલવાથી સીટનું ધોવાણ થાય છે અને પ્રવાહને નુકસાન થાય છે.

ઉચ્ચ પ્રારંભિક ખર્ચ: સામગ્રીના આધારે, તુલનાત્મક ગેટ વાલ્વ કરતાં ઘણીવાર વધુ ખર્ચાળ.

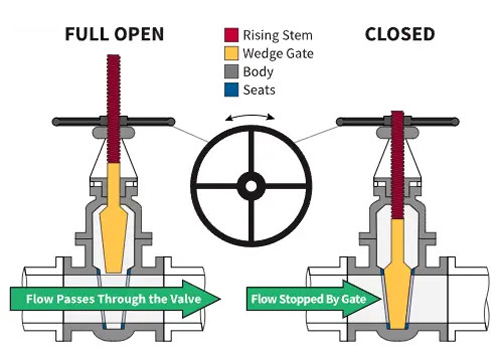

ગેટ વાલ્વ: ફુલ-ફ્લો આઇસોલેશન વાલ્વ

ગેટ વાલ્વપ્રવાહને લંબરૂપ સ્લાઇડિંગ ગેટ અથવા વેજનો ઉપયોગ કરો. ગેટ ઊંચો કરવાથી પ્રવાહનો માર્ગ (ન્યૂનતમ પ્રતિકાર) સંપૂર્ણપણે સાફ થાય છે, જ્યારે તેને નીચે કરવાથી સીલ બને છે. મુખ્યત્વે અમર્યાદિત પ્રવાહ માટે વપરાય છે જ્યાં ભાગ્યે જ કામગીરી થાય છે.

ગેટ વાલ્વ લાક્ષણિકતાઓ:

ડિઝાઇન: જટિલ ગેટ મિકેનિઝમ્સ સાથે વધતા અથવા વધતા ન હોય તેવા દાંડીઓ ધરાવે છે.

કામગીરી: સંપૂર્ણ ખુલ્લા/બંધ સ્થાનો માટે બહુવિધ હેન્ડલ ટર્ન (ધીમા ઓપરેશન) ની જરૂર પડે છે.

પ્રવાહ કામગીરી: સંપૂર્ણપણે ખુલ્લું હોય ત્યારે નજીવા દબાણ ઘટાડા સાથે પૂર્ણ-બોર પ્રવાહ માટે ઑપ્ટિમાઇઝ કરેલ.

સીલિંગ: સમય જતાં સીટ અને સ્ટેમ લીકેજ થવાની સંભાવના, ખાસ કરીને ઉચ્ચ દબાણ હેઠળ.

ગેટ વાલ્વના ફાયદા:

ન્યૂનતમ દબાણ નુકશાન: જ્યારે સંપૂર્ણપણે ખુલ્લું હોય ત્યારે સીધો પ્રવાહ માર્ગ પ્રવાહ કાર્યક્ષમતાને મહત્તમ બનાવે છે.

ખર્ચ-અસરકારકતા: સામાન્ય રીતે બોલ વાલ્વ કરતા ઓછી ખરીદી કિંમત.

મોટા વ્યાસની યોગ્યતા: અવરોધ વિનાના પ્રવાહની જરૂર હોય તેવી મોટી પાઇપલાઇનો માટે પસંદગીનું.

ગેટ વાલ્વના ગેરફાયદા:

ધીમી કામગીરી: મલ્ટી-ટર્ન મિકેનિઝમ ઝડપી પ્રતિભાવ જરૂરિયાતોને અવરોધે છે.

સીલ ડિગ્રેડેશન: સીટ/વેરને નુકસાન અથવા સ્ટેમ પેકિંગ નિષ્ફળતાને કારણે લીકેજ થવાની સંભાવના.

થ્રોટલિંગ અસંગતતા: આંશિક રીતે ખુલ્લી સ્થિતિઓ કંપન, ગેટ/સ્કાઉરિંગ અને સીલને નુકસાન પહોંચાડે છે.

મહત્વપૂર્ણ તફાવતો: બોલ વાલ્વ વિ ગેટ વાલ્વ

1. સંચાલન સિદ્ધાંત:

બોલ વાલ્વ: ક્વાર્ટર-ટર્ન રોટેશનલ ગતિ (90°).

ગેટ વાલ્વ: મલ્ટી-ટર્ન રેખીય ગતિ (ઊભી ગેટ ગતિ).

2. પ્રવાહ નિયંત્રણ ક્ષમતા:

બોલ વાલ્વ: ચુસ્ત શટઓફ સુપિરિયર; થ્રોટલિંગની ભલામણ કરવામાં આવતી નથી.

ગેટ વાલ્વ: ફક્ત સંપૂર્ણ ખુલ્લું/બંધ; થ્રોટલિંગ ગંભીર નુકસાન પહોંચાડે છે.

3. સીલિંગ અખંડિતતા:

બોલ વાલ્વ: ઉચ્ચ દબાણ હેઠળ, ખાસ કરીને ઉચ્ચ સીલિંગ.

ગેટ વાલ્વ: સ્લાઇડિંગ સંપર્ક સપાટીઓને કારણે લીક થવાની સંભાવના વધુ હોય છે.

4. ખર્ચ અને જાળવણી પરિબળો:

બોલ વાલ્વ: વધુ પ્રારંભિક ખર્ચ, ઓછી આજીવન જાળવણી જરૂરિયાતો.

ગેટ વાલ્વ: ઓછો પ્રારંભિક ખર્ચ, ઘસારો/સીલથી જાળવણીમાં વધારો થવાની સંભાવના.

5. પ્રાથમિક ઉપયોગો:

બોલ વાલ્વ: ગેસ લાઇન, ઓઇલ સિસ્ટમ, વારંવાર સાયકલિંગ, કટોકટી બંધ (HVAC, પ્રક્રિયા નિયંત્રણ).

ગેટ વાલ્વ: પાણીની મુખ્ય પાઇપલાઇનો, સિંચાઈ, ગંદુ પાણી, ભાગ્યે જ કામકાજ જેમાં સંપૂર્ણ પ્રવાહની જરૂર પડે છે.

નિષ્કર્ષ: શ્રેષ્ઠ વાલ્વ પસંદ કરવો

બોલ વાલ્વ અને ગેટ વાલ્વ મહત્વપૂર્ણ છતાં અલગ ભૂમિકા ભજવે છે.બોલ વાલ્વ પસંદ કરોગંભીર શટઓફ, વારંવાર કામગીરી અને શ્રેષ્ઠ લીક નિવારણ માટે.ગેટ વાલ્વ પસંદ કરોજ્યારે ખર્ચ-સંવેદનશીલ હોય, ત્યારે મોટા પાઈપોમાં ફુલ-બોર ફ્લોની જરૂર હોય છે, અને કામગીરી ભાગ્યે જ થાય છે. આ મુખ્ય તફાવતોને સમજવાથી - ઓપરેશનની ગતિ, સીલિંગ કામગીરી, પ્રવાહ લાક્ષણિકતાઓ અને ખર્ચ માળખું - શ્રેષ્ઠ વાલ્વ પસંદગીની ખાતરી થાય છે, નવી ડિઝાઇન અને જાળવણી અપગ્રેડ બંને માટે તમારા પાઇપિંગ ઇન્ફ્રાસ્ટ્રક્ચરની કાર્યક્ષમતા, સલામતી અને આયુષ્યમાં વધારો થાય છે.

પોસ્ટ સમય: ફેબ્રુઆરી-૧૦-૨૦૨૫